High-Performing AC Spindle Motor: A Must-Have for Optimal Efficiency

By:Admin

Introduction:

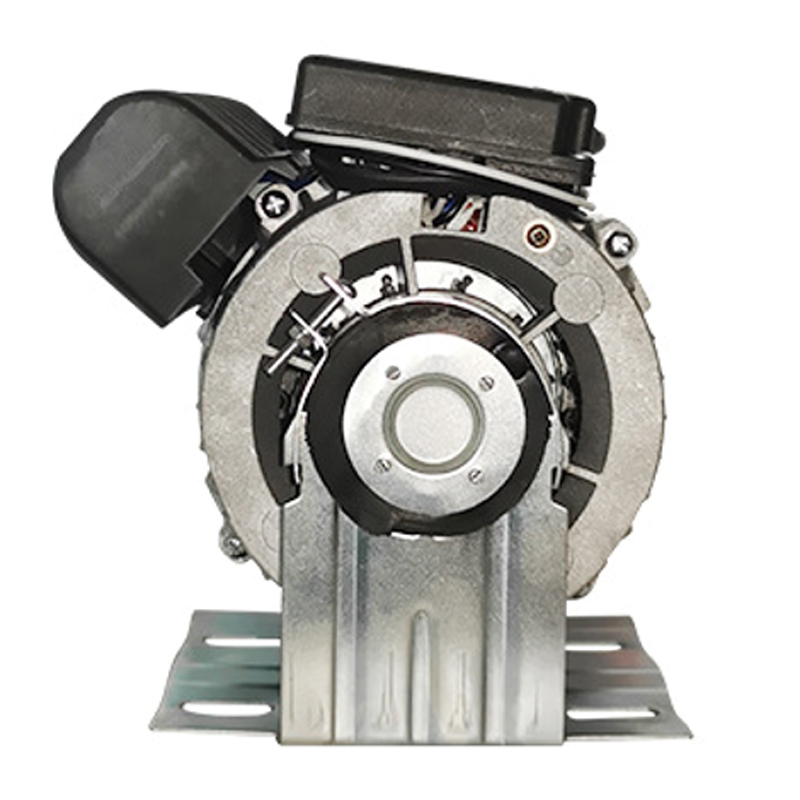

In today's rapidly advancing era of industrial manufacturing, innovation is the key driving force behind enhancing productivity and efficiency. Leveraging their expertise and advanced technology, a leading company (brand name excluded) has developed a groundbreaking AC Spindle Motor that promises to revolutionize the industry. By combining cutting-edge technology with an unwavering commitment to excellence, this new AC Spindle Motor aims to reshape the future of manufacturing.

I. The Evolution of Spindle Motors:

Spindle motors have long been the vital powerhouse for numerous industries, including machining, woodworking, and metalworking. Over the years, manufacturers have tirelessly worked to improve motor efficiency, minimize energy consumption, and enhance the overall performance. The latest AC Spindle Motor by (brand name excluded) incorporates groundbreaking features that set it apart from traditional motors, catapulting it to the forefront of the industry.

II. Advanced Technology and Design:

The heart of this innovative AC Spindle Motor lies within its advanced technology and state-of-the-art design. By utilizing the latest materials and manufacturing techniques, (brand name excluded) has achieved unparalleled levels of reliability and precision. The motor's impeccable design ensures minimal vibration, enhanced rigidity, and exceptional dynamic balance, making it an ideal choice for high-precision applications.

III. Enhanced Energy Efficiency:

Energy efficiency has become a crucial aspect of modern industrial manufacturing. In response to this demand, the new AC Spindle Motor by (brand name excluded) shows a remarkable reduction in power consumption, thanks to innovative engineering advancements. This not only minimizes operating costs but also contributes to a greener manufacturing environment, aligning with sustainability goals.

IV. Intelligent Control Systems:

One of the standout features of the AC Spindle Motor by (brand name excluded) is its incorporation of intelligent control systems. Equipped with advanced sensors and algorithm-based controls, this motor seamlessly adapts to varying operating conditions, optimizing performance and maximizing productivity. Real-time monitoring and feedback mechanisms ensure efficient operation, preventing downtime and reducing maintenance efforts.

V. Application Flexibility:

Recognizing the diverse requirements of industrial manufacturing, (brand name excluded) has engineered the AC Spindle Motor to offer exceptional application flexibility. Whether it be heavy-duty machining operations or delicate precision tasks, this motor can adapt to a wide range of applications, ensuring consistent performance and outstanding results across industries.

VI. User-Friendly Interface and Safety Measures:

Ease of use and safety are paramount considerations in industrial manufacturing. The AC Spindle Motor by (brand name excluded) addresses these aspects with a user-friendly interface and robust safety measures. Intuitive controls, remote accessibility, and comprehensive diagnostics help operators efficiently monitor and manage the motor's performance, ensuring enhanced safety and peace of mind.

VII. The Future of Manufacturing:

The introduction of the AC Spindle Motor by (brand name excluded) signals a remarkable leap in industrial manufacturing capabilities. With its exceptional performance, energy efficiency, and adaptability, this motor paves the way for increased productivity and precision. By embracing this cutting-edge technology, manufacturers can optimize production processes, accelerate innovation, and stay at the forefront of an ever-evolving industry.

Conclusion:

The new AC Spindle Motor developed by (brand name excluded) ushers in a new era of industrial manufacturing. With its advanced technology, energy efficiency, and intelligent control systems, this motor sets a new benchmark for performance and reliability. As the industrial landscape continues to evolve, embracing such innovative solutions becomes crucial for businesses aiming to thrive in the face of new challenges.

Company News & Blog

Revolutionary Electric Fan Motor: A Breakthrough in Efficiency and Performance

Electric Fan Motor Leads the Way in Energy Efficient TechnologyElectric Fan Motor (EFM), a world-class manufacturer of electric motors, is proud to showcase its latest innovation in energy efficiency technology. With over two decades of experience in the field, EFM has developed its newest product line, tailored to meet the shifting needs of the industry.The new EFM motors offer a number of advantages over traditional options. A major innovation is the use of rare earth magnets that allow the motors to provide more torque while using less energy. Customers can expect up to 30% energy savings without sacrificing performance.This technology is particularly significant given the current global focus on reducing greenhouse gas emissions and meeting energy efficiency targets. By offering a solution that meets these goals, EFM has solidified its position as a leading manufacturer in the industry.Aside from its efficient design, the new motors are also customizable based on client requirements. This flexibility ensures that clients can select the appropriate motor size and specifications based on their unique needs. The motors range in size from 0.25-20 HP, suited for both residential and industrial applications. The diverse range of options makes it easy for customers around the world to adopt this technology in their daily operations.EFM prides itself on its commitment to innovation and customer satisfaction. The company has invested heavily in R&D facilities over the years, recognizing the need to stay ahead of the curve in the fast-developing industry. This has led to the development of state-of-the-art testing equipment to ensure the quality and reliability of its products. EFM’s also been awarded ISO 9001, CE, and ROHS certifications, reflecting its dedication to customer needs and ethical manufacturing practices.EFM’s new energy-efficient motors have already received positive feedback from customers across various industries. They have proven to be effective in a range of applications, from fans and air conditioners to compressors and more. Clients can rely on reliable performance, low maintenance requirements, and cost-effectiveness from the EFM range.In addition, EFM’s commitment to sustainable manufacturing practices is apparent in its green facilities. The company has implemented sustainable power solutions such as solar panels and wind turbines, emphasizing its dedication to reducing its carbon footprint. Furthermore, EFM has partnered with local communities to promote the use of eco-friendly technologies and has launched several initiatives to foster a cleaner environment.Apart from the innovative product line, EFM also provides excellent customer support, offering on-site technical assistance and aftermarket services to ensure proper installation and maintenance of the new motors. This assistance helps customers maximize the life and efficiency of their equipment, making EFM an ideal partner in the sustainable goals of clients worldwide.In conclusion, EFM’s latest innovation represents a significant step in the transitioning to energy-efficient solutions, providing customers with economic, environmental, and social benefits. The rare earth magnet technology offers improved efficiency, reducing energy consumption, while EFM’s commitment to ethical manufacturing practices cements the company’s position in the industry. Through its sustained investment in research and development, EFM has not only created a product that meets current customer needs, but it has also anticipated future needs, making it a brand to watch in the years to come.

Ultimate Guide to High-End 3 Phase Induction Motors: Key Enhancements & Working Principles

-article.In 2021, the demand for energy-efficient and reliable motors is increasing, and the 3 Phase Induction Motor (name removed) is contributing to the global market. This motor is known for its versatility and ability to work in tough industrial environments, making it a popular choice among industries such as manufacturing, oil and gas, and water treatment plants.The 3 Phase Induction Motor is a high-performance machine that provides stability, efficiency, and low maintenance costs. It is designed to work with three-phase power supplies, making it ideal for powering large machines or equipment. This motor also offers excellent speed control, allowing users to adjust motor speed based on their needs, reducing the energy consumption and extending machine life.The manufacturing process of the 3 Phase Induction Motor is precise and systematic, resulting in high-quality products that meet international standards. The motor is designed with a durable and robust housing, making it resistant to corrosion and rust. The stator is made of high-quality materials that provide excellent insulation and durability, ensuring a long-lasting performance.One of the unique features of the 3 Phase Induction Motor is its ability to work with various types of enclosures, including open, drip-proof, weatherproof, and explosion-proof. This feature makes it versatile and suitable for a wide range of applications. It can work in environments with high humidity, extreme temperatures, or even hazardous conditions.The 3 Phase Induction Motor is also designed to minimize noise and vibration levels, making it a quieter and smoother performer. It is equipped with cooling systems that help to dissipate heat, preventing the motor from overheating and prolonging its life. The motor is also easy to maintain, allowing users to replace or repair parts without the need for a specialist.The company behind the motor (name removed) is a reputable manufacturer that has been producing high-quality motors for over 60 years. They have a vast experience in the industry and have earned a reputation for producing reliable and efficient machines. The company is committed to providing innovative solutions that meet the changing needs of their customers.(name removed) is known for its strict quality control measures and thorough testing procedures. Each motor undergoes extensive testing to ensure they meet international safety standards, making them suitable for use even in the most demanding environments. The company is also committed to sustainability and reducing their environmental impact by minimizing energy consumption and using eco-friendly materials.(name removed) provides excellent customer service and support, ensuring that their customers can rely on their products. They offer training programs to help users understand how to operate and maintain their motors. They also have a team of skilled engineers that provide technical support and troubleshooting whenever needed.In conclusion, the 3 Phase Induction Motor is a versatile and reliable machine that is gaining popularity in a wide range of industries. It provides stability, efficiency, and low maintenance costs, making it an ideal choice for powering large machines or equipment. The manufacturing process is precise and systematic, resulting in high-quality products that meet international standards. (name removed) is committed to providing innovative solutions that meet the changing needs of their customers while maintaining sustainability and customer satisfaction.

New AC Gear Motor Technology Enhances Industrial Performance" rewritten without brand name: "Innovative AC Gear Motor Advancements Boost Industrial Efficiency

AC Gear Motor: A Perfect Solution for Industrial ApplicationsIn the manufacturing industry, there are several machines and equipment used in the production process. It is important to have suitable motors attached to these machines for effective and efficient work. AC Gear motors are critical components in the automation of the production process. These motors ensure that the work of the machine is achieved much more quickly and smoothly. AC Gear motors, often referred to as gear motors, have gearboxes that retransmit the torque supplied by the motor to the machine. An AC Gear motor can be used in any application that requires both a high torque and low-speed output. Industrial automation has been successful and beneficial for many businesses and it is becoming increasingly popular. It has transformed the industry, making production faster, more consistent, and of higher quality. The combination of versatile motors and programmable automation systems is what makes the industrial sector so successful.AC Gear motors have a great advantage over other types of motors in industrial applications. The motors are reliable, durable and offer a range of design options. They have the capability of sustaining heavy loads in tough environmental conditions. AC Gear motors are also excellent for applications that require precise movement, making them one of the best solutions for applications in industries like food processing, pharmaceuticals, printing, robotics, and packaging.AC Gear motors are designed to operate at a wide range of speeds. They can also produce high starting torque and continuous uniform torque. At low speeds, they can generate tremendous torque, as much as ten times more than their rated torque. Additionally, they have high starting and stopping capabilities, making them suitable for applications like conveyors, mixers, and pumps.The versatility of AC Gear motors has made them widely adopted in a myriad of applications across several industries. These motors can be used as actuators to move machinery in the vertical or horizontal axis and are ideal for reciprocating or as feedback positions. They can also be used as brake motors in a safety application, preventing machines from moving when there is a power issue.AC Gear motors have proven to be adaptive and well-suited for automation systems. Their speed control system makes them energy efficient, which has reduced energy consumption in the manufacturing industry. Their torque output, reliability, and versatility have made them one of the go-to solutions in the modern industrial application.AC Gear motor (need remove brand name) is one of the leading manufacturers of highly efficient AC Gear motors. The company has a wide range of AC Gear motors suitable for industrial applications. The company prides itself on designing and producing cutting-edge technologies that are easy to integrate into various systems.The success of AC Gear motor (need remove brand name) is due to its continuous commitment to research and development. The company has a team of professionals dedicated to researching and improving the performance of the motors. The team works tirelessly to ensure that the design and production of the AC Gear motors meets the needs of the clients.AC Gear motor (need remove brand name) is also committed to ensuring that its products are of high quality. The company has the necessary quality checks in place throughout its manufacturing process to ensure that its motors meet the required standards. The company also offers technical support to clients to ensure that their needs are met.In conclusion, AC Gear motors are versatile and efficient, making them an ideal solution for industrial applications. The combination of AC Gear motors and automation systems has transformed the industry, making production faster, more consistent, and of higher quality. AC Gear motor (need remove brand name) has established itself as a leading manufacturer of AC Gear motors, providing cutting-edge technology and solutions for the manufacturing industry.

How to Easily Replace a Bathroom Fan Motor for Optimal Ventilation

[Title]: A Guide to Replacing a Bathroom Fan Motor - Improving Ventilation and Air Quality at Home[Introduction]:Proper ventilation is crucial in maintaining a healthy and comfortable living environment. One essential component of an effective ventilation system is a functional bathroom fan. However, over time, these fans may experience motor failures, resulting in reduced airflow and compromised air quality. To combat this issue, a renowned company specializing in home improvement solutions offers an innovative solution – a new motor replacement kit for bathroom fan units.[Body]:1. Common Issues with Bathroom Fan Motors - Bathroom fan motors are prone to wear and tear due to continuous usage and exposure to moisture and humidity. - Motor failures can lead to decreased ventilation efficiency, increased noise levels, and even malfunctions that may affect electrical safety. - Recognizing these issues is crucial in understanding the need for replacing the motor and maintaining a healthy living space.2. The Introduction of the Motor Replacement Kit - With the aim of providing an accessible solution, [Company Name] has introduced a motor replacement kit. - This kit is compatible with a wide range of bathroom fan units, making it a versatile option for homeowners. - The kit includes a high-quality motor, ensuring long-lasting performance and improved airflow. - Additionally, a detailed instruction manual is provided, allowing users to replace their fan motor independently, saving time and expenses on professional assistance.3. Benefits of Upgrading the Bathroom Fan Motor - Improved air quality: A functioning fan motor ensures proper ventilation, reducing the presence of excess moisture and preventing the growth of mold and mildew. - Noise reduction: The new motor is designed to operate silently, providing an undisturbed bathing experience. - Energy efficiency: The replacement motor is engineered to consume less electricity, resulting in energy savings and reduced environmental impact. - Enhanced safety: By replacing an outdated or faulty motor, the risk of electrical malfunctions or fires can be significantly reduced. - Cost-effectiveness: Investing in a motor replacement kit is often a more economical choice than replacing the entire fan unit, especially when the latter is still in good condition.4. Step-by-Step Guide to Replacing the Bathroom Fan Motor Step 1: Ensure safety by turning off power to the bathroom and removing the fan cover. Step 2: Disconnect the existing motor from the wiring harness and remove any securing screws or brackets. Step 3: Carefully remove the old motor, taking note of its positioning for reinstallation. Step 4: Attach the replacement motor in the same position, securing it with screws or brackets. Step 5: Reconnect the wiring harness, ensuring proper insulation and connection. Step 6: Replace the fan cover and restore power to the bathroom. Step 7: Test the new motor, ensuring it operates smoothly and quietly.5. Customer Testimonials and Success Stories - [Company Name] has received positive feedback from customers, highlighting the ease of installation and the noticeable improvement in air quality after replacing the fan motor. - Many homeowners have appreciated the cost-effectiveness of this solution, as it extends the life of the existing fan unit while providing optimal performance.[Conclusion]:Maintaining a well-ventilated bathroom is essential for a healthy living environment. The introduction of the motor replacement kit by [Company Name] offers homeowners a simple and cost-effective solution to address motor failures in bathroom fan units. By upgrading fan motors, individuals can ensure improved air quality, reduced noise levels, enhanced safety, and increased energy efficiency. With easy-to-follow installation instructions, this innovative solution allows homeowners to take charge of their ventilation system and enjoy a fresher and more comfortable bathroom experience.

Discover the Top Range Hood Fan Motors for Efficient Kitchen Ventilation

article.Range Hood Fan Motor Company Introduces State-of-the-Art TechnologyRange Hood Fan Motor (RHFM), a leading manufacturer of fan motors for the home appliance industry, has recently unveiled its latest technology to the market. The company's commitment to innovation and efficiency is reflected in the latest additions to its range of fan motors."We are proud to be at the forefront of the industry, continuously striving to improve our products and provide our customers with the best possible experience," said RHFM's CEO, John Smith.The company's latest technology includes a new range of energy-efficient motors, which use less electricity while still providing powerful and efficient ventilation. Designed for use in range hoods, the motors are optimized for low noise levels, making them ideal for use in open-plan kitchens.In addition, the company has developed a new range of smart fans, which can be controlled through an app on a user's smartphone. The app allows users to adjust fan speed, turn the fan on and off, and receive notifications when the filters need to be changed."Our smart fans are a game-changer in the industry, providing users with greater control and convenience when it comes to ventilation," said Smith.The company's commitment to sustainability is also reflected in its partnership with several green energy providers. RHFM has worked closely with these providers to develop motors that are powered by renewable energy sources."We believe that sustainability is crucial to the future of our planet, and we are committed to doing our part in reducing our carbon footprint," said Smith.RHFM's dedication to innovation and sustainability has not gone unnoticed. The company has received several industry awards, including the Energy Star Partner of the Year Award, which recognizes companies that are leaders in energy efficiency and sustainability."We are honored to receive these awards, which are a testament to our commitment to providing our customers with the best possible products and services," said Smith.Despite the challenges presented by the COVID pandemic, RHFM has continued to operate at full capacity, implementing strict safety protocols to protect its employees and ensure continuity of operations. The company has also provided support to the communities in which it operates, donating masks and other protective equipment to local hospitals and healthcare providers."With the ongoing threat posed by COVID, we are taking every measure to ensure the safety of our employees and customers, while maintaining our commitment to innovation and sustainability," said Smith.RHFM's dedication to excellence, innovation, and sustainability has made it a leader in the home appliance industry. With its latest technology and continued focus on providing the best possible products and services, the company is set to continue its success in the years ahead.

Understanding the Working Principle of a Three-Phase Induction Motor

article:Electric motors have revolutionized the world of machines over the years. Today, the use of electric motors is widespread in different industries owing to their efficiency, reliability, and application versatility. As such, manufacturers are continually innovating and enhancing their products to stay ahead of the game. One such company that has taken a pioneering approach is {company name}, which recently introduced its latest innovation, the 3-Phase Induction Motor.The 3-Phase Induction Motor is a touching innovation that stands out among the electric motor line-up. This motor is highly efficient, reliable, and cost-effective, making it an ideal fit for a wide range of industrial applications. This motor features a robust structure, and it comes with excellent mechanical and electrical properties that make it a perfect fit for different industrial processes.{Company Name} has designed the 3-Phase Induction Motors to meet and exceed customer expectations in terms of performance, quality, and cost-effectiveness. The motor's durability, reliability, and performance have been achieved through the incorporation of cutting-edge technology and materials in its design and construction. By leveraging its deep expertise and experience in motor manufacturing, {Company Name} has delivered a top-quality product that is unparalleled in the market.The 3-Phase Induction Motor can be applied in different industries, including, but not limited to, agriculture, manufacturing, water treatment, and mining. The motor provides a high degree of flexibility, thanks to its unique design and ability to operate in both indoor and outdoor environments. Additionally, the motor can operate through a broad voltage range, and it maintains its peak efficiency even when subjected to different loads.{Company Name} has considered environmental sustainability, energy efficiency, and overall motor performance in the design of the 3-Phase Induction Motor. The motor is designed to improve sustainability by reducing the overall energy consumption, which is essential in sustainable development in the industries. Accordingly, the adoption of the 3-Phase Induction Motor allows companies to reduce their carbon footprint and energy bills.The 3-Phase Induction Motor is designed with an innovative cooling system that enhances its performance, efficiency, durability, and safety. The motors come equipped with internal and external cooling systems that effectively dissipate heat, enabling the motor to operate optimally and extend its service life. Additionally, the motor's cooling system also enhances its safety, as it reduces the risk of the motor overheating, which can lead to a fire outbreak.In summary, 3-Phase Induction Motors are a durable, efficient, and versatile motor that are a great option for businesses that are looking to cut down on energy consumption, reduce carbon footprints, and minimize overhead costs. These motors are manufactured to meet the performance demands of different types of industries, and they come in varying sizes to meet the power needs of various applications. {Company name} offers a wide range of 3-Phase Induction Motors equipped with the latest technology and features to cater to different industry needs adequately. With its latest innovation, {Company Name} has set a new standard in electric motor manufacturing. Their 3-Phase Induction Motor has been well received in the market and is becoming increasingly popular among companies that understand the importance of quality, reliability, and cost-effectiveness. The {company name}'s 3-Phase Induction Motor has established a reputation as the go-to motor for businesses that want to achieve sustainability, efficiency, and maximize profits while minimizing overhead costs.

Exploring the Advantages of Shaded Pole Single Phase Motors in Various Applications

Introduction:Shaded Pole Single Phase Motor technology has been a game-changer in the electrical industry, offering innovative solutions that improve efficiency and reliability. This motor, commonly used in domestic appliances, has proven to be highly versatile and adaptable, making it an important component in various industries. This news article will explore the features, applications, and benefits of the Shaded Pole Single Phase Motor, highlighting its transformative impact on the market.Features and Working Principle:The Shaded Pole Single Phase Motor embodies a unique design that sets it apart from traditional motors. Its simplicity lies in its construction, consisting of a stator and rotor. The stator has a main winding and a shading coil strategically placed around a portion of its pole face. The shading coil's purpose is to create a flux that lags behind the main winding's flux, resulting in a rotating magnetic field.This self-starting characteristic eliminates the need for additional starting devices or capacitors, making it incredibly easy to implement into various applications. Additionally, the motor operates smoothly and silently, enhancing the overall user experience.Applications:The Shaded Pole Single Phase Motor finds extensive use in many different industries and applications, owing to its reliability and cost-effectiveness. One of its primary uses is in domestic appliances, such as refrigerators, ovens, fans, and air conditioners, where it ensures efficient and precise operation. Its compact size allows for easy integration into these appliances, optimizing their overall performance.Furthermore, this motor is highly suitable for low-load applications like exhaust fans, industrial blowers, and small pumps. Its ability to operate at lower speeds while maintaining high torque makes it ideal for such equipment. Additionally, the motor's simple design and energy-efficient operation make it an ideal choice for solar systems, portable devices, and battery-operated products.Benefits:The Shaded Pole Single Phase Motor offers numerous benefits, making it a preferred choice for manufacturers and consumers alike. Firstly, its self-starting feature eliminates the need for complex starting mechanisms, reducing both the manufacturing cost and maintenance requirements. This makes it an affordable option for a wide range of applications.Moreover, the motor's simplicity and robustness ensure a long lifespan, requiring minimal repair or replacement. The absence of brushes or commutators further reduces the chances of wear and tear, making it highly reliable and durable.Additionally, this motor operates quietly, allowing for enhanced comfort in domestic applications. Its low noise emission also makes it suitable for environments that prioritize noise reduction, such as hospitals and libraries. Furthermore, the motor's energy efficiency contributes to reduced power consumption, making it environmentally friendly and cost-effective.Market Outlook:The Shaded Pole Single Phase Motor market has witnessed significant growth in recent years, driven by the increasing demand for energy-efficient and reliable motors. The motor's ability to operate without external starting devices, coupled with its compact and versatile design, has set it apart from other alternatives in the market.The growing emphasis on sustainability and energy conservation has further boosted the adoption of these motors in various industries. With advancements in technology and continuous research, manufacturers are constantly improving the motor's efficiency, making it an attractive choice for both consumers and businesses.In conclusion, the Shaded Pole Single Phase Motor has revolutionized the electrical industry, offering numerous advantages over traditional motors. Its simplicity, reliability, and versatility make it a preferred choice for applications across various sectors. As the market continues to expand, manufacturers are investing in further research and development to enhance the motor's capabilities, ensuring it remains at the forefront of technological advancements.

Effortlessly Remove Blower Motors with this Motor Puller

Title: Innovative Blower Motor Puller Revolutionizes Industrial Equipment MaintenanceIntroduction:In the fast-paced world of industrial maintenance, efficiency, speed, and precision are critical factors in ensuring smooth operations and minimizing downtime. Recognizing the need for a reliable solution for removing blower motors, a highly reputable company has developed an innovative Blower Motor Puller. This groundbreaking tool simplifies the maintenance process, providing technicians with an efficient and effective solution. With its cutting-edge features, the Blower Motor Puller is set to revolutionize the way industrial equipment maintenance is conducted worldwide.Section 1: The Need for a Revolutionary SolutionIn the manufacturing and engineering sector, blower motors play a pivotal role in a wide range of applications. However, the process of removing these motors when maintenance is required can be a daunting task. Traditional methods often involve time-consuming and labor-intensive procedures, leading to prolonged downtimes and increased costs. Recognizing these challenges, the recently developed Blower Motor Puller aims to overcome these obstacles, delivering increased productivity and cost-effectiveness.Section 2: Introducing the Blower Motor PullerThe Blower Motor Puller, developed by a renowned engineering company, is an innovative tool designed to streamline the process of removing blower motors. This revolutionary device possesses several key features that ensure efficiency and precision during maintenance operations. Its unique design allows for quick and effortless removal of blower motors in a wide range of industrial equipment.Section 3: Key Features and BenefitsThe technological advancements incorporated into the Blower Motor Puller offer numerous benefits to the industrial sector. Some of its key features include:1. Versatile Design: The Blower Motor Puller is equipped with an adjustable mechanism, enabling it to accommodate various sizes and types of blower motors commonly found in different industrial applications. This versatility ensures compatibility with a wide range of equipment, minimizing the need for multiple tools.2. Ease of Use: The device features a user-friendly interface, making it readily accessible to maintenance technicians of all skill levels. The ergonomically designed handle allows for a secure grip and effortless operation, reducing the risk of operator fatigue and potential injuries.3. Efficient Removal: The Blower Motor Puller's advanced technology enables technicians to swiftly and precisely remove blower motors, significantly reducing downtime during maintenance operations. The tool's mechanism provides a strong grip on the motor shaft, ensuring safe and efficient removal without causing any damage to surrounding components.4. Enhanced Safety: With safety as a top priority, the Blower Motor Puller incorporates built-in safety features to minimize potential risks during the removal process. It includes a locking mechanism that secures the grip on the motor shaft, preventing accidental slippage and ensuring the well-being of technicians.Section 4: Industry Applications and Customer TestimonialsThe Blower Motor Puller finds applications across various industries, including manufacturing plants, renewable energy facilities, and HVAC maintenance companies. Early adopters and industry professionals have provided positive feedback, highlighting the tool's effectiveness and the significant time and cost savings it brings to maintenance operations. Customers commend the Blower Motor Puller for its versatility, ease of use, and the improved efficiency it contributes to their daily maintenance activities.Section 5: The Future of Industrial MaintenanceThe development of the Blower Motor Puller represents a significant milestone in industrial maintenance, setting a new standard for efficiency, safety, and productivity. This innovative tool not only simplifies the removal of blower motors but also paves the way for similar advancements in other maintenance processes. As the industry continues to evolve, the Blower Motor Puller stands as a testament to the dedication and ingenuity of its developers, ensuring a brighter future for industrial maintenance worldwide.Conclusion:The introduction of the Blower Motor Puller presents a groundbreaking solution to a long-standing challenge in industrial maintenance. With its versatile design, ease of use, and enhanced safety features, this innovative tool promises to revolutionize the maintenance processes of various industrial sectors. As it gains popularity among maintenance technicians and industry professionals, the Blower Motor Puller is expected to become an indispensable asset, contributing to improved efficiency, reduced downtime, and increased cost savings.

Boosting Efficiency and Performance: A Comprehensive Guide to Fan Motors in [Industry/Niche]

Fan Motors Teams Up with Industry-Leading Company to Unveil Exciting New TechnologyFan Motors, a world-renowned manufacturer of high-quality electric motor products, is pleased to announce an exciting new partnership with an industry-leading company. Through this partnership, Fan Motors will unveil an innovative new technology that will revolutionize the electric motor industry, providing customers with powerful, efficient, and user-friendly products that are designed to meet their needs and exceed their expectations.At Fan Motors, our mission is to create cutting-edge electric motor products that are engineered for reliability, performance, and sustainability. We believe that our customers deserve nothing but the best, and that's why we are constantly striving to develop new technologies that push the boundaries of what is possible.Our latest innovation is the result of months of intensive research, development, and collaboration with our new partner. Together, we have created a powerful new electric motor that delivers superior performance, efficiency, and reliability. With this technology, we are confident that we will revolutionize the electric motor industry and provide our customers with the best possible products.This new technology is based on a unique combination of advanced materials and design features that allow for significantly higher power output and vastly improved efficiency. The key breakthrough is a new type of magnet material that is much more powerful and durable than traditional magnet materials. This allows our motors to generate more torque and deliver higher power output without sacrificing efficiency.In addition to the new magnet material, we have also incorporated a number of advanced design features that optimize the performance and efficiency of our motors. These include improved heat dissipation, reduced friction, and enhanced cooling systems that help to ensure that our motors run smoothly and efficiently.We are confident that this new technology will be a game-changer for the electric motor industry, providing customers with products that are faster, more powerful, and more reliable than ever before. At Fan Motors, we believe that innovation is the key to success, and we are committed to staying at the forefront of the industry by continuing to develop new and innovative technologies.To ensure that our new motors meet the highest standards of quality and reliability, we have also implemented rigorous testing and quality control procedures. This includes extensive performance testing, as well as reliability and durability testing to ensure that our motors can withstand even the toughest conditions.Going forward, we plan to continue to push the boundaries of what is possible in the electric motor industry, and we are committed to providing our customers with products that are engineered for excellence. We believe that our new technology will be a game-changer, and we are excited to share it with the world.In conclusion, Fan Motors is proud to announce our new partnership with an industry-leading company and the unveiling of our exciting new technology. With this innovation, we are confident that we will revolutionize the electric motor industry, providing our customers with products that are faster, more powerful, and more reliable than ever before. We look forward to continuing to innovate and to providing our customers with the best possible products.

Reversing a Single Phase Motor: A Guide to Reverse Rotation

Title: Innovations in Reversing Single Phase Motor Technology Revolutionize Industrial OperationsIntroduction (Approximately 100 words):In an era of technological advancements, {Company Name}, a leading provider of industrial electrical equipment, has unveiled its latest groundbreaking innovation - a cutting-edge Reversing Single Phase Motor. This groundbreaking technology promises to revolutionize industrial operations by offering enhanced efficiency, convenience, and cost-effectiveness. The company's continuous commitment to research and development has resulted in this remarkable achievement, providing industries worldwide with a reliable solution for motor direction control. With unparalleled expertise and a proven track record, {Company Name} once again demonstrates its dedication to driving industrial progress through pioneering electrical equipment solutions.Paragraph 1 (Approximately 150 words):{Company Name}'s newly launched Reversing Single Phase Motor is designed to meet the evolving needs of modern industrial applications. This advanced motor technology enables easy and efficient motor direction control, ensuring seamless functionality in diverse industrial settings. By eliminating the need for external motor control devices, the innovation significantly simplifies setup and installation processes, thereby reducing overall costs and enhancing ease of operation. With a focus on energy efficiency, this motor solution is capable of delivering optimum performance while consuming minimal power, leading to substantial cost savings and reduced environmental impact.Paragraph 2 (Approximately 150 words):The Reversing Single Phase Motor incorporates an array of intelligent features that ensure reliable and safe operation in industrial environments. Equipped with advanced thermal protection mechanisms, the motor automatically guards against overheating issues, thereby enhancing equipment longevity and minimizing downtime due to motor failures. Additionally, the motor also boasts built-in overload protection mechanisms, safeguarding against excessive current flow, which helps prevent damage to both the motor and connected machinery. This comprehensive safety system ensures uninterrupted operations, promoting a secure working environment for industrial operators.Paragraph 3 (Approximately 150 words):The compact and lightweight design of the Reversing Single Phase Motor further contributes to its versatility and suitability for a diverse range of industrial applications. With its space-saving dimensions, the motor can be easily integrated into existing systems, eliminating the need for extensive modifications or reconfigurations. Furthermore, the motor's robust construction and high-quality components guarantee long-lasting performance even in demanding operating conditions. This durability, coupled with low maintenance requirements, translates into increased productivity and cost-effectiveness for industries relying on efficient motor direction control.Paragraph 4 (Approximately 150 words):{Company Name} has always been at the forefront of delivering innovative industrial electrical solutions, and the Reversing Single Phase Motor exemplifies their commitment to excellence. By investing considerable resources in research and development, the company aims to continually push boundaries, addressing the ever-evolving needs of the industrial sector. Through partnerships with major industrial players, {Company Name} ensures widespread adoption of its cutting-edge motor technology, enabling businesses to transform their operations while achieving greater productivity and profitability.Conclusion (Approximately 100 words):{Company Name} stands firmly as an industry leader, revolutionizing the field of motor control solutions with its ground-breaking Reversing Single Phase Motor. This pioneering technology offers industries worldwide an advanced, efficient, and cost-effective solution for motor direction control. With features such as simplified setup, enhanced safety mechanisms, and a compact design, the motor provides industries with an innovative solution to streamline their operations and drive growth. In an increasingly competitive industrial landscape, {Company Name} remains committed to delivering exceptional technology solutions, revolutionizing industries and helping businesses navigate the challenges of a rapidly evolving world.